We, Chamunda Pack Tech, established in the year 1976 and have been ever growing since then as manufacturers, exporters, and suppliers of packaging, form filling, and sealing machines. Our comprehensive range of product includes Automatic Packing Machines like Multi Head Packing Machine, VFFS Pouch Packing Machine, Collar Type Packing Machine, Automatic Form Fill & Sealing Machine etc…

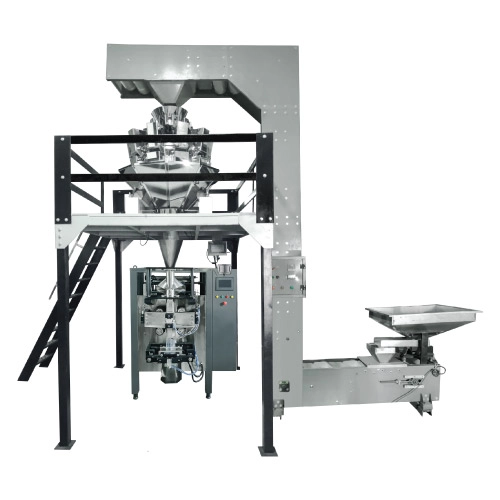

Muti-Head

Four-Head

Cup-Filler

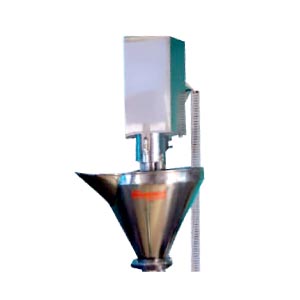

Servo-Auger

This multihead weigher packing machine is suitable for packing light weight, high value free flow or entangled products…

Four head linear weigher machine is weighmatric material feeding system means a features with highly accurate weighing…

Servo auger are used for filling and sealing non free flowing powders. This collar type center seal pouch packaging machine uses Auger as filler and…

Cup fillers are an economical alternative for volumetric filling of free flowing products. The concept is actually quite…

At Chamunda Pack Tech, we take pride in transforming your vision into reality. From the initial idea to the final implementation, we deliver solutions that enhance your production efficiency and reliability, making your packaging process seamless and effective.

Ask us anything—we’re here to provide the answers you need!

Below you will find answer of common question asked related packing machines

A collar type packing machine is a packaging device designed to fill and seal various products into pre-formed pouches or bags. It features a collar-like structure that holds the pouch open during the filling process. This type of machine is commonly used for packaging granular, powdered, or liquid products.

The machine works by using a collar to support the pouch while it is filled with the product. The process typically involves:

Collar type packing machines are versatile and can handle a wide range of products, including:

Some key advantages include:

You can consider the following factors:

or just contact us we will be happy help you

We see ourselves as partners to our customers, working closely to develop solutions that deliver both technical and economic success. Our key advantages include: